What Is PCB Assembly? Expert Guide to Process & Methods

Printed circuit boards (PCBs) are the backbone of modern electronics, but they are only functional once assembled. This guide explains what is PCB assembly, the process involved, and the methods that matter most today.

At Arrival Electronics Limited, years of hands-on experience ensure every assembly meets industry standards. Understanding the PCB assembly process is essential for anyone involved in product design, manufacturing, or quality control. With the right approach, PCB assemblies deliver long-term reliability and performance across industries.

What You Need to Know

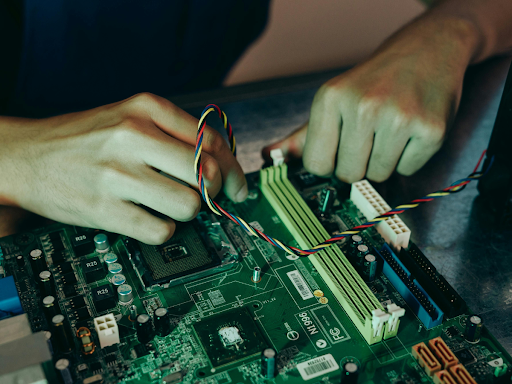

PCB assembly (PCBA) is the process of mounting electronic components onto a printed circuit board to create a fully functional device. Unlike PCB fabrication, which produces the bare board, assembly adds resistors, capacitors, ICs, and connectors through soldering.

Precision assembly solutions support both prototypes and production runs, ensuring consistent reliability and performance in every build. By following industry standards such as IPC-A-610, the assembly process reduces defects and extends product lifespan. Understanding what is PCB assembly is essential for anyone involved in electronics design and manufacturing.

PCB Assembly vs. PCB Fabrication

PCB fabrication and PCB assembly are often confused, but they serve very different purposes in the electronics manufacturing process. PCB fabrication refers to producing the bare board, which includes creating copper traces, layering the substrate, etching, drilling, and plating. The result is a non-functional board essentially the canvas for what comes next.

PCB assembly, on the other hand, involves installing electronic components onto the fabricated board. This stage uses methods such as surface-mount technology (SMT), through-hole technology (THT), and reflow soldering to build a fully functional circuit board.

The key takeaway is simple: fabrication creates the canvas, while assembly brings the board to life.

How PCB Assembly Works

1. Solder Paste Application

A stencil applies solder paste to pads where components will be placed.

Automated printers ensure precision for high-density designs.

2. Component Placement

SMT machines place chips, resistors, and capacitors at rapid speeds.

Manual placement may be used for larger or irregular components.

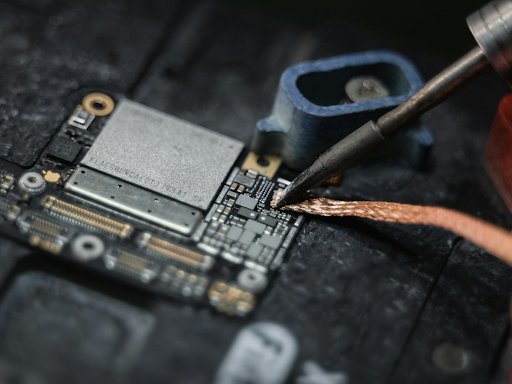

3. Soldering Methods

Reflow Soldering: Standard for SMT. Boards pass through an oven where solder melts and bonds.

Wave Soldering: Common for THT. The underside of the board passes over molten solder.

4. Inspection & Quality Control

Automated Optical Inspection (AOI) verifies correct placement.

X-ray inspection checks hidden joints such as BGAs.

Manual inspection ensures compliance with IPC standards.

5. Functional Testing

Power-up tests confirm operational performance.

Environmental tests (thermal cycling, vibration) ensure reliability for critical industries.

Methods of PCB Assembly

Surface Mount Technology (SMT)

Components mounted directly onto the PCB surface.

Advantages: Compact, fast, supports high-density circuits.

Common in smartphones, IoT devices, and consumer electronics.

Through-Hole Technology (THT)

Leads inserted into drilled holes and soldered.

Advantages: Strong mechanical bonds, reliable in stress environments.

Common in automotive, aerospace, and industrial electronics.

Mixed Technology

Combines SMT and THT for designs needing both compactness and durability.

Key Developments in PCB Assembly for 2025

Smart Factories and Automation

UK PCB facilities are increasingly adopting Industry 4.0 practices, where robotics and connected machinery streamline production and cut human error.Flexible and Wearable PCB Demand

The rise of medical wearables and foldable electronics is pushing growth in flexible PCB assembly methods, making boards thinner and more adaptable.Advanced Thermal Management

With 5G and high-speed electronics generating more heat, manufacturers are prioritizing new materials and assembly techniques to improve thermal dissipation.Localized Manufacturing Growth

The push for reshoring in the UK means more PCB assembly is being handled domestically, reducing reliance on overseas suppliers and strengthening supply stability.Stringent Compliance Standards

Sectors like automotive EVs and defense are driving higher certification and compliance requirements, influencing how PCBs are assembled and tested.

Best Practices for a Reliable PCB Assembly

Design for Manufacturability (DFM): Ensure Gerber files are assembly-ready.

Choose the Right Technology: Match SMT or THT to your product needs.

Partner with Certified Providers: IPC and ISO-certified partners ensure quality.

Plan for Testing: Include functional and stress testing early in the project.

Consider Lifecycle & Environment: Factor in heat, vibration, and compliance requirements.

Why PCB Assembly Quality Matters in Every Project

Quality in PCB assembly goes far beyond appearance. A well-assembled board ensures reliable performance, long-term durability, and compliance with industry standards. In sectors like medical devices, automotive, and aerospace, even a minor defect can lead to safety concerns, product recalls, or costly downtime.

By focusing on precision engineering, thorough inspections, and adherence to IPC-A-610 standards, every project benefits from consistent performance and reduced risk. Whether producing a small prototype or scaling up to full production, maintaining high assembly quality is essential to meeting both technical requirements and customer expectations.

FAQ Section

Q1: What is the process in simple terms?

It’s about attaching electronic components to a blank board, turning it into a functional circuit. This is the stage that gives devices their ability to operate.

Q2: What are the main steps involved?

Typical stages include solder paste application, component placement, soldering, inspection, and testing. Each step plays a role in ensuring reliability and performance.

Q3: What is the difference between fabrication and assembly?

Fabrication creates the empty board, while assembly installs the components to make it operational. Think of it as the difference between building a frame and finishing the whole machine.

Q4: Which is better: SMT or THT?

SMT is best suited for compact, high-speed devices, while THT works better for products needing durability under tough conditions. The right choice depends on the project requirements.

Q5: Do you provide services in the UK?

Yes, local support is available across the UK with quick turnaround and strict quality checks. This also helps reduce lead times and logistics costs.

Ensuring Success in Every Build

Understanding what is PCB assembly and how processes and methods differ helps businesses make informed choices. Whether you need SMT for compact devices or THT for rugged environments, Arrival Electronics Limited delivers trusted UK-based solutions.

Ready to discuss your next project? Get in touch today through the website’s contact page.