Assembled PCB Guide to Build Smarter, Faster, Reliable Boards

For engineers and businesses, high-quality assembled PCB boards are critical to delivering reliable electronics. Arrival Electronics Limited provides expert PCB assembly services that combine efficiency, precision, and durability, helping your projects move from prototype to production seamlessly. With years of experience handling both prototype and small-to-medium volume runs, they ensure every board meets strict quality standards.

Their team collaborates closely with clients to minimize errors, streamline production, and accelerate time-to-market, delivering solutions that perform flawlessly in demanding applications. By leveraging advanced equipment and industry best practices, they consistently produce boards that exceed client expectations.

What Is a Fully Populated Board?

A fully populated board, or assembled PCB, is a printed circuit board with all electronic components installed and soldered. Unlike bare boards, it is ready for integration into devices.

Types of PCB Assembly

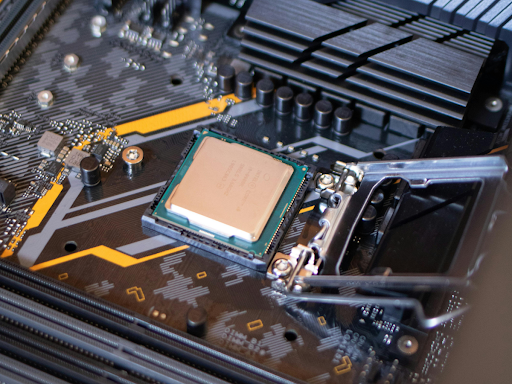

Surface-Mount Technology (SMT): Small, automated components for high-density boards.

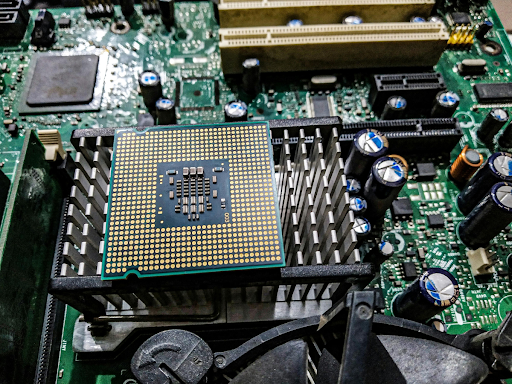

Through-Hole Technology: Components inserted into drilled holes, offering mechanical strength.

Mixed Technology: Combines SMT and through-hole for versatile designs.

Example: Using a combination of SMT and through-hole assembly, a complex IoT board was completed with greater precision, resulting in significantly fewer defects during testing. This approach also improved overall production efficiency, allowing the board to move from prototype to final product more quickly.

PCB Assembly Services You Can Rely On

Choosing a trusted PCB assembly service ensures quality, speed, and cost-efficiency. Services typically include:

Prototype Assembly: Quick turnaround for design testing.

Small to Medium Volume Production: Flexible runs for startups and established businesses.

Custom Assembly Solutions: Tailored layouts for unique project requirements.

A reliable provider also implements strict quality control measures to minimize errors and ensure consistent performance across all boards.

How to Choose the Right PCB Assembly Services

Selecting the best provider affects your product’s reliability. Consider:

Experience and Certifications: ISO 9001 or IPC-A-610 compliance.

Equipment and Technology: Automated SMT lines and inspection systems.

Lead Times and Flexibility: Ability to handle prototypes and small batches.

Testing and QA: Functional testing, X-ray inspection, and solder quality checks.

Data Point: Using precise SMT and through-hole assembly techniques combined with thorough testing can reduce defects in high-density PCBs by up to 30%, improving overall reliability. This approach ensures that both prototype and full production runs meet strict quality standards, minimizing costly rework and delays.

Key Trends Shaping PCB Innovation in 2025

Eco-Friendly and Lead-Free Assemblies – Many clients now demand environmentally friendly PCB assembly. Lead-free solder and green processes are highly relevant to modern assembly practices.

Miniaturization & HDI Boards – High-density interconnect (HDI) boards are becoming standard in electronics, and assembling smaller components requires precision. This is directly related to the overall quality and reliability of the boards.

Smart Inspection Automation – Automated optical inspection (AOI) or AI-assisted testing improves defect detection, helping ensure consistently high-quality results.

Rapid Prototyping – Prototype production is a core part of PCB services; faster turnaround is a key advantage for businesses looking to test and refine designs quickly.

IoT Integration – IoT devices are a growing segment of electronics. Producing boards for these devices often involves more complex layouts, making this trend highly relevant to modern assembly practices.

Common PCB Assembly Challenges

Even experienced teams encounter issues. Key challenges include:

Misaligned SMT components

Solder bridging or cold joints

Component shortages during production

Thermal stress causing board warping

Tip: These challenges can be effectively managed with automated component placement, high-precision reflow ovens, and thorough quality assurance processes.

Effective Strategies to Improve PCB Assembly

Use standard components to simplify procurement and maintain consistent quality. This approach also reduces the risk of delays caused by hard-to-source parts.

Optimize board layouts to reduce layer counts and improve manufacturing efficiency. Streamlined layouts can shorten production time and minimize potential errors during assembly.

Combine SMT and through-hole techniques strategically to enhance durability and performance. This ensures critical components are securely mounted while maintaining high-density designs.

Work with experienced assembly services to ensure reliable results and efficient production. Skilled teams can implement best practices that improve yield and reduce post-production defects.

Why Work with Experienced PCB Specialists

Over 10 years of PCB assembly experience.

State-of-the-art SMT lines and testing equipment.

Flexible services for prototypes, small batches, and large production.

Proven reliability for industries including IoT, medical, and industrial electronics.

Frequently Asked Questions About PCB Assembly

What is a fully assembled board?

A fully assembled board has all electronic components mounted and soldered, ready for immediate use. This ensures devices can be tested and integrated without additional assembly steps.How do I choose a reliable assembly service?

Look for experience, certifications, testing capabilities, and flexibility. It’s also important to review past projects or client feedback to gauge quality and consistency.What are the common issues in assembly?

Misalignment, solder defects, and thermal stress are frequent problems. Proper processes and thorough inspection can significantly reduce these risks.Can I order small batch assemblies?

Yes, many providers offer prototype and low-volume runs. This allows businesses to test designs and make adjustments before full-scale production.What types of assembly are available?

Surface-mount, through-hole, and mixed technology assemblies are common options. Choosing the right method depends on the complexity, size, and durability requirements of the board.How long does assembly usually take?

Prototype runs may take a few days, while full production runs depend on volume and complexity. Planning ahead and coordinating with the assembly provider can help meet tight deadlines.

Moving from Design to Reality

High-quality assembled PCB boards are essential for delivering reliable and efficient electronics projects. Ensuring precise design, careful production, and thorough testing can make all the difference in performance and durability.

Arrival Electronics Limited provides expert guidance through every step, from design to production, ensuring boards meet the highest standards. Get in touch today to start the next project and experience fast, reliable, and high-quality PCB assembly solutions. Don’t wait to bring electronics projects to life with precision and efficiency.