Efficient PCB Manufacturing Assembly for Superior Quality

At Arrival Electronics Limited, we understand the importance of high-quality PCB manufacturing assembly in creating the reliable electronic devices that power the world today. Whether you're developing consumer gadgets, industrial equipment, or medical devices, the process of assembling printed circuit boards (PCBs) is vital to ensuring that your product performs as expected and is built to last.

In this article, we’ll walk you through the fundamentals of PCB manufacturing assembly, explain why it's crucial for your project, and explore the different steps involved. We'll also highlight how our experience and commitment to quality make us a trusted partner for all your PCB manufacturing and assembly needs.

The PCB Creation and Assembly Process

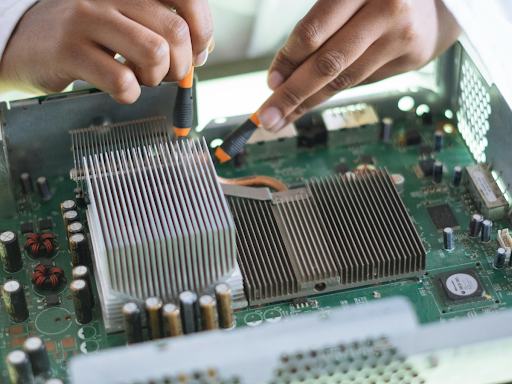

PCB manufacturing assembly is the process of fabricating and assembling the electronic components onto a PCB. These boards serve as the backbone of nearly every electronic device, connecting the various components and allowing them to work together. A PCB is made of layers of conductive pathways that interconnect different parts, like resistors, capacitors, and microchips.

The manufacturing process includes designing the layout of these pathways, producing the board itself, and then assembling the components onto it. Proper assembly is crucial because even a small error in the placement or soldering of a component can result in device failure or malfunction.

Our team ensures the precise manufacturing and assembly of PCBs, allowing our clients to trust in the quality and functionality of their end products.

Why PCB Assembly Matters

A well-executed manufacturing process results in products that are both durable and efficient. Poor assembly, however, can lead to several issues, such as:

Reliability concerns: Faulty connections or weak solder joints can result in short circuits, device failure, or overheating.

Costly delays: Inaccurate or low-quality assembly can cause costly rework, wasting valuable time and resources.

Safety risks: Faulty boards can compromise the safety of the product, which is especially critical in sectors like medical or automotive applications.

By choosing a reliable PCB manufacturer, you can be confident that each step of the manufacturing assembly process will be carried out meticulously, reducing the risk of costly mistakes and ensuring that your products meet safety and quality standards.

The PCB Manufacturing Process

The PCB manufacturing process involves several key steps, each of which is essential to ensuring a high-quality product. Here’s an overview of the main stages involved:

Designing the PCB Layout

This is the very first step in creating a PCB, where the overall design is determined. Engineers use specialized software tools to create a schematic, which defines the connections between all components. They then design the physical layout of the PCB to ensure components fit properly and that there are no short circuits.Printing the PCB

Once the design is finalized, the next step is to manufacture the board itself. This typically involves etching a thin layer of copper on a substrate (usually fiberglass or resin), leaving only the necessary conductive pathways. The board is then cleaned and prepared for the assembly process.Placing Components

The next step is placing the components onto the board. This is often done using machines that precisely position each part. In some cases, the placement may be done manually for smaller, more delicate components. Regardless of the method, ensuring that each component is in the correct place is critical to the overall functionality of the product.Soldering the Components

Once the components are placed on the PCB, they are soldered into place. This can be done using wave soldering or reflow soldering, depending on the type of components and the board’s design. Reflow soldering is most common for surface-mount components, while wave soldering is used for through-hole components. Soldering must be done with precision to create strong, durable connections.Testing and Inspection

After the assembly is complete, rigorous testing is carried out to ensure the PCB functions as expected. This can include electrical tests, visual inspections, and sometimes even more advanced techniques like X-ray inspection to identify hidden issues. We employ thorough quality control measures to ensure that every PCB assembly meets the highest standards.

Key Challenges in PCB Manufacturing

There are several challenges that manufacturers face during the PCB assembly process. Being aware of these challenges can help you better understand how we approach them to deliver high-quality results:

Component Sourcing: Obtaining the right components on time can be a challenge, especially when working with complex or custom designs. We work closely with trusted suppliers to ensure that we have access to the highest-quality components.

Precision in Placement: Even small errors in the placement of components can result in failures. Our team uses advanced placement machines that ensure the highest degree of accuracy, reducing the risk of errors and improving product quality.

Cost Management: PCB manufacturing assembly can be expensive, particularly when producing small batches or working with complex designs. We offer cost-effective solutions by using efficient processes and sourcing affordable materials without compromising on quality.

Regulatory Compliance: Some industries, such as medical or aerospace, require PCBs to meet specific regulatory standards. We ensure that all of our products comply with the necessary certifications, so you don’t have to worry about meeting industry-specific requirements.

The Benefits of Choosing Our PCB Assembly Service

We take pride in providing top-notch PCB manufacturing and assembly services. Here’s why you should trust us with your next project:

Expertise

Our team has years of experience in the PCB manufacturing industry. We work with a wide range of industries, including consumer electronics, automotive, medical, and industrial sectors. Our in-depth knowledge allows us to tackle even the most complex PCB designs with precision and efficiency.High-Quality Standards

We adhere to strict quality control processes at every stage of the PCB assembly process. From sourcing components to the final inspection, we ensure that every board meets the highest industry standards. Our focus on quality ensures that your products are reliable and durable.Customization

Every project is different, and we understand that your needs may vary. Whether you require a specific type of PCB material, a certain board size, or a custom assembly process, we can tailor our services to meet your exact requirements.Efficient Turnaround

Time is of the essence in any project, and we’re committed to delivering results on time. Thanks to our efficient manufacturing and assembly processes, we can provide quick turnarounds, ensuring your product hits the market faster.Customer-Centric Approach

Our clients are at the heart of everything we do. We work closely with you to understand your needs and provide the best possible solutions. Our goal is to help you achieve your project’s objectives while maintaining high-quality standards and budget efficiency.

Ensuring Quality and Precision

At Arrival Electronics Limited, we’re committed to providing our clients with top-quality manufacturing and assembly services. From the initial design to final inspection, we ensure that every step of the process is completed with precision and care. Whether you’re working on a new product or need an experienced partner to handle your assembly, we have the expertise and dedication to help bring your vision to life.

By choosing us for your project, you can rest assured that you're working with a trusted partner who values expertise, experience, and quality. Let us help you bring your products to life with reliable, high-quality solutions that meet the highest industry standards.

If you’re ready to take the next step, contact us today at arrivalelectronics.co.uk to learn more about our PCB manufacturing and assembly services.