Understanding Printed Circuit Board Assembly in Detail

In electronics manufacturing, PCBA (Printed Circuit Board Assembly) plays a crucial role in turning designs into functional products. Whether you are an engineer, a business owner seeking dependable electronics assembly, or simply interested in how devices are constructed, understanding the manufacturing process is essential. Arrival Electronics Limited, backed by years of industry experience and a solid reputation, offers a clear and informative guide on the process, its significance, and why collaborating with an expert partner makes all the difference.

What Is PCBA?

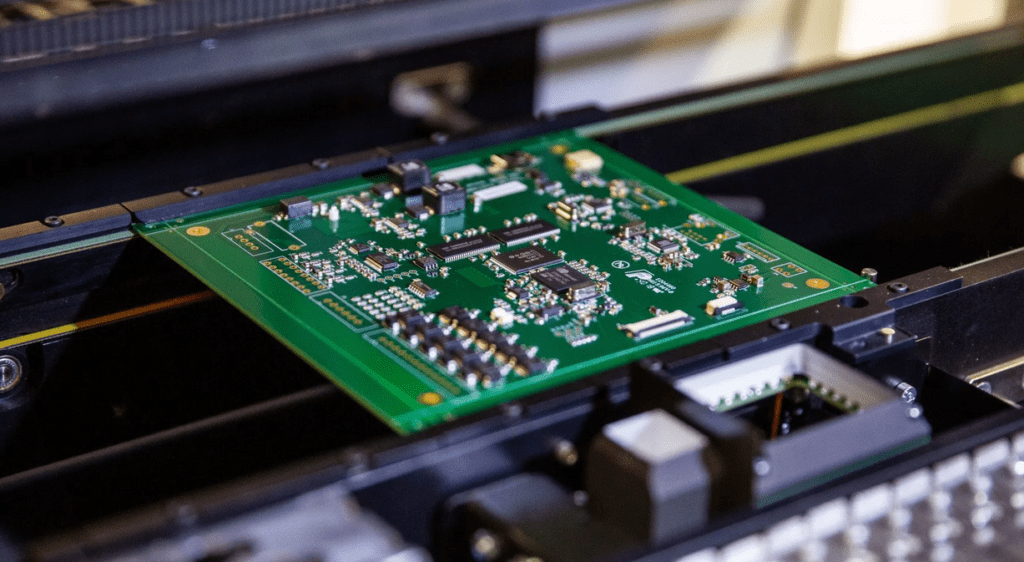

The assembly involves mounting electronic components onto a printed circuit board to create a fully functional electronic circuit. This step is essential in the electronics industry, connecting the design phase with the final product.

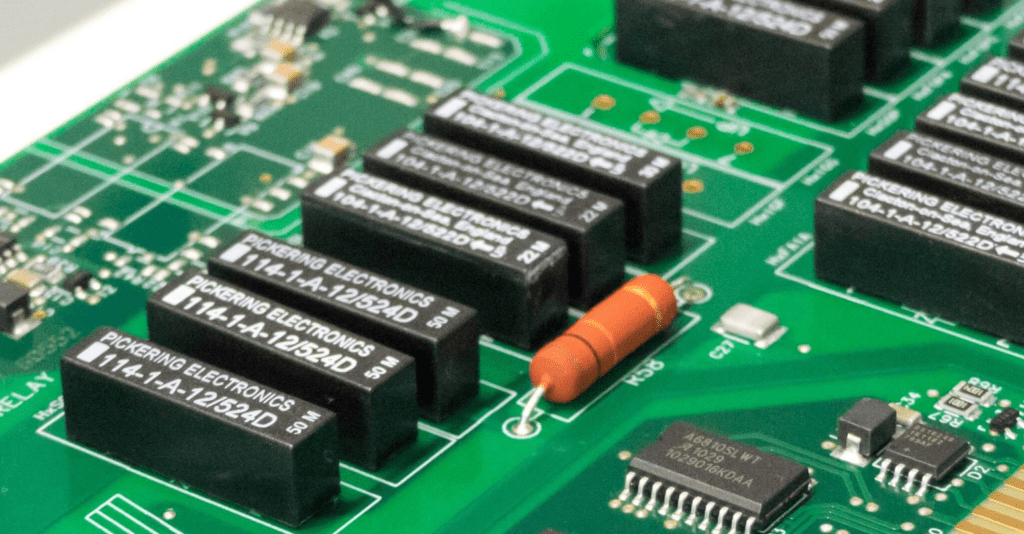

A printed circuit board is a flat board made from insulating material with conductive pathways etched or printed onto its surface. Components like resistors, capacitors, microchips, and connectors are placed and secured onto these pathways during assembly. Once completed, this assembled board acts as the core foundation of electronic devices, allowing them to operate as intended.

The Crucial Role of Circuit Assembly in Electronics Manufacturing

The quality and reliability of electronic assembly directly impact the performance and durability of finished products. Inadequate assembly can result in device malfunctions, higher costs, and harm to a company’s reputation. Because of this, the assembly process demands precision, technical expertise, and advanced equipment.

Each project presents unique challenges, whether it’s a prototype or a large-scale production run. By implementing rigorous quality control procedures and following industry-standard manufacturing practices, these processes consistently meet the highest standards expected in today’s market.

Precision, Reliability, and Support: Complete Technical and Production Services

We provide an integrated range of technical services, production capabilities, and supply chain solutions to meet the needs of advanced electronic manufacturing. Every process is guided by industry standards and a commitment to quality, ensuring consistent results from prototype to full-scale production.

Technical Services & Standards

IPC Class 3 compliance for high-reliability applications

First-off inspection processes to ensure build accuracy

Advanced 3D Automated Optical Inspection (AOI)

BGA X-ray for internal joint validation

Golden first-off sample reference

In-circuit testing (ICT) for component-level checks

Full functional testing for end-use reliability

RoHS compliance for environmental responsibility

First Article Inspection Reports (FAIR)

Production Services

Assembly of complex printed circuit boards

Full box build and end-product assembly

Rapid-turn prototyping for early-stage development

Scalable serial production

Conformal coating for environmental protection

Robotic soldering for consistent precision

Ultra-small component placement (case size 01005)

Multi-level Bill of Materials (BoM) management

Product serialisation and full traceability

Ongoing technical support at every stage

Supply Chain Solutions

Finished goods and component stock holding

Just-in-Time (JIT) and Just-in-Sequence (JIS) delivery

Kanban-based inventory replenishment

Engineering Change Notice (ECN) revision control

Full traceability from procurement to delivery

AS9120B certified systems for aerospace-grade assurance

Custom packaging and logistics tailored to your product

Cable assembly capabilities

Distribution support for complete supply chain integration

Key Stages of the Circuit Board Assembly Process

Solder Paste Application: This involves applying a thin layer of solder paste to the PCB where components will be placed. Accuracy in this step is critical for ensuring strong electrical and mechanical connections.

Component Placement: Automated machines or skilled technicians position components on the board according to the design specifications. Precision is vital to avoid errors that affect the product's function.

Reflow Soldering: The PCB with components passes through an oven where the solder paste melts and solidifies, permanently attaching components to the board.

Inspection and Testing: Every assembled board undergoes thorough inspection, often using automated optical inspection (AOI), X-ray, and functional tests to verify assembly quality and performance.

Final Assembly and Packaging: Completed PCBAs are integrated into their final products or shipped as standalone units ready for further use.

A Strategic Approach to Electronic Manufacturing

They have built a strong reputation through a commitment to quality, reliability, and customer satisfaction. Their approach is grounded in a deep understanding of electronic assembly processes and advanced manufacturing capabilities.

Expertise: With a team of experienced engineers and technicians, the company is equipped to manage complex designs and tackle challenging projects with expertise. Their knowledge covers various industries, including automotive, medical, telecommunications, and consumer electronics.

Experience: Years of hands-on experience ensure they understand the nuances of PCBA, including how to avoid common pitfalls such as component misplacement, soldering defects, and contamination.

Authoritativeness: The company strictly adheres to international standards such as IPC-A-610 for electronics assembly and ISO certifications for quality management. This dedication underscores its commitment to delivering products that meet global expectations.

Trustworthiness: Clear communication and transparency are prioritized throughout the production process. Clients receive detailed updates and quality reports, along with access to expert advice to support well-informed decisions.

Advantages of Partnering with a Specialist Electronics Manufacturer

Choosing the right manufacturing partner is crucial for the success of any electronics project. Working with a specialist offers several important benefits, including:

Consistency in Quality: Specialist manufacturers have the equipment and expertise to maintain consistent assembly quality, reducing the risk of defects and recalls.

Faster Time to Market: Experienced teams streamline processes to meet deadlines without compromising quality, allowing clients to efficiently bring their products to market.

Cost Control: By optimizing manufacturing processes and minimizing errors, specialist manufacturers help manage overall production costs.

Technical Support: Access to knowledgeable engineers who can advise on design for manufacturability (DFM) and troubleshoot issues during production.

Flexibility: Can handle everything from small prototype runs to high-volume production, adapting to the client’s needs.

Common Challenges in Electronic Manufacturing and How They Are Addressed

Manufacturing electronic assemblies is complex, and challenges can occur at multiple stages. Below are some common issues and how these are effectively managed to ensure smooth production and quality results:

1. Component Placement Accuracy

Challenge: Incorrect placement can lead to malfunctioning circuits or short circuits.

Solution: They use high-precision pick-and-place machines and manual inspection to ensure components are positioned exactly as required.

2. Solder Joint Defects

Challenge: Poor soldering can cause weak connections, leading to intermittent or permanent failures.

Solution: Controlled reflow soldering processes and thorough inspection methods, like X-ray and AOI, ensure reliable solder joints.

3. Electrostatic Discharge (ESD)

Challenge: Sensitive components can be damaged by electrostatic discharge during assembly.

Solution: The facility is equipped with ESD-safe workstations, and staff are trained in ESD handling procedures to protect components.

4. Testing and Quality Control

Challenge: Detecting faults early to prevent defective products from reaching clients.

Solution: Multiple testing layers, including in-circuit and functional testing, are employed to identify and resolve issues before shipment.

Industries Served

Comprehensive manufacturing solutions are offered to various sectors, each with unique demands and strict quality standards. These industries include:

Medical Devices: Manufacturing electronic assemblies for medical devices requires the highest quality and traceability to comply with regulatory standards.

Automotive: Components must withstand harsh conditions such as temperature fluctuations and vibrations.

Telecommunications: Requires high-speed, reliable circuit boards for communication devices.

Consumer Electronics: Focus on cost-effectiveness, compact designs, and durability.

Their extensive experience allows them to meet the specific needs of each industry while maintaining excellent quality standards.

How to Choose the Right Electronics Manufacturing Partner

Choosing the right manufacturing partner is a critical decision. Here are key factors to consider when evaluating potential suppliers:

Manufacturing Expertise: Does the manufacturer have proven experience with the types of assemblies needed?

Quality Certifications: Look for ISO certifications and adherence to IPC standards.

Technology and Equipment: Advanced machinery reduces errors and improves efficiency.

Communication: Transparent reporting and accessible customer support are essential.

Capacity and Scalability: Ensure the manufacturer can handle your production volumes and timelines.

The Future of Electronics Manufacturing: Innovation and Precision Ahead

While the fundamentals of electronic assembly remain consistent, technological advancements continue to improve the process. Innovations such as flexible circuit boards, surface-mount technology (SMT), and advanced testing techniques help manufacturers deliver better products more efficiently.

Companies stay current with industry trends and invest in ongoing staff training and equipment upgrades. This commitment ensures clients benefit from the latest capabilities while receiving consistently high-quality assemblies.

Getting in Touch for Your Electronic Manufacturing Needs

For businesses looking for reliable electronic assembly services, expert support is available from the first consultation through to final delivery. Their website, www.arrivalelectronics.co.uk, provides detailed information about their services and contact options.

Clients can reach out for a quote, technical advice, or to discuss project requirements directly with their expert team. Every inquiry is treated with care, with a strong focus on building lasting partnerships grounded in trust and a commitment to quality.

Conclusion

Printed Circuit Board Assembly is critical in electronics manufacturing, impacting product reliability, performance, and cost. Choosing an experienced, knowledgeable, and trustworthy electronics manufacturer can significantly influence the success of an electronics project.

Arrival Electronics Limited brings years of experience, expert knowledge, and a commitment to quality, making them a strong partner for businesses seeking dependable manufacturing solutions. Their thorough process, adherence to standards, and focus on customer satisfaction ensure that every assembly meets exacting requirements.

For those seeking dependable electronic manufacturing solutions, experienced providers offer the technical knowledge and service needed to confidently navigate today’s production demands. If you're looking for services that focus on precision, consistency, and reliability, visit the provider’s website or reach out to their team to discuss your project requirements.