Dependable PCB Assembly Solutions for Every Application

At Arrival Electronics Limited, we understand that PCB assembly is a critical step in the electronics manufacturing process. Whether you are developing prototypes, small runs, or large-scale production, the quality and precision of your assembly directly impacts the reliability and performance of your final product.

In this article, we will walk you through the essentials of the process, the services we provide, and why working with us ensures that your projects meet the highest standards of quality and efficiency.

Understanding the Process

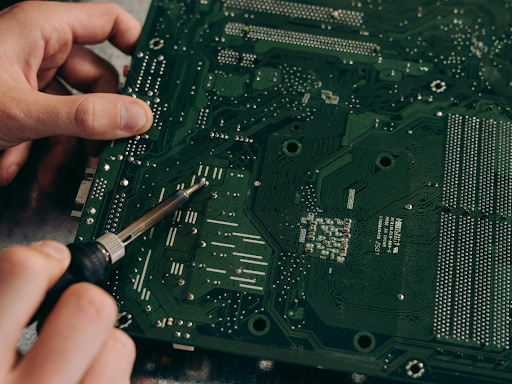

This process involves attaching electronic components to a printed circuit board to create a functional electronic device. The board itself serves as the foundation, with copper tracks and pads providing electrical connections between components.

The assembly includes placing and soldering parts such as resistors, capacitors, integrated circuits, and connectors according to a detailed design. The completed board then functions as part of an electronic system, whether in consumer devices, industrial machinery, or medical equipment.

Ensuring Reliable Performance

Precision and reliability are essential. Poor soldering, incorrect component placement, or substandard materials can lead to device failures, which might result in costly recalls, safety issues, or downtime.

This is why every step of the assembly process must be handled with care and expertise. Our commitment to quality begins with sourcing reliable components and materials. We use industry-standard processes and conduct rigorous inspections to ensure that every product we deliver meets your exact specifications.

Our Services

We offer a comprehensive range of assembly services designed to meet the diverse needs of our clients:

Prototype Assembly

For new product development, prototyping is a vital phase. We assist clients in creating prototypes to validate designs and make necessary adjustments before mass production. Our team works closely with you to assemble prototypes with speed and accuracy, supporting your innovation process.

Small to Medium Volume Production

Many customers require reliable assembly for small to medium production runs. Whether you are launching a niche product or need a pilot batch, we provide flexible and cost-effective solutions. Our processes maintain consistent quality while allowing for adaptability in order quantities.

High Volume Production

For large-scale manufacturing, we leverage efficient production lines with automated placement and soldering technologies. This approach ensures timely delivery without compromising quality, supporting your supply chain demands.

Surface Mount Technology (SMT) Assembly

SMT is a widely used method where components are mounted directly onto the surface of boards. This allows for compact, high-density circuits. Our SMT process utilizes precision equipment and trained operators to handle complex designs.

Through-Hole Assembly

Though less common than SMT in modern electronics, through-hole technology remains essential for certain applications requiring strong mechanical bonds or specific electrical characteristics. We provide expert through-hole assembly using both manual and automated soldering techniques.

Mixed Technology Assembly

Many boards combine both SMT and through-hole components. Our mixed technology assembly service integrates both methods seamlessly, ensuring complete functionality and durability.

What Sets Us Apart

Our team brings years of experience and technical knowledge to every project. Here are some key reasons clients trust us for their needs:

Expertise and Industry Knowledge

We understand the complexities of PCB design and assembly, and stay current with industry standards such as IPC-A-610 and IPC J-STD-001. This enables us to deliver assemblies that meet or exceed quality requirements.

Quality Control and Testing

Every assembly undergoes thorough inspection. We use automated optical inspection (AOI), X-ray analysis for solder joint integrity, and functional testing to ensure reliability. Our quality control measures help reduce defects and support long-term product performance.

Customer-Centric Approach

Your requirements guide our processes. We work collaboratively to understand your technical needs, production schedules, and budget constraints. Clear communication and transparency are cornerstones of our service.

Flexibility and Scalability

Whether your project demands a few prototypes or thousands of units, we can adjust our resources and processes accordingly. This flexibility ensures you receive efficient service without unnecessary overhead.

Commitment to Delivery

Timely delivery is essential in the fast-paced electronics market. Our streamlined workflow and supply chain management help us meet deadlines and support your time-to-market goals.

Our Manufacturing Steps

Understanding the steps involved can help you appreciate the care and precision we bring to your project:

Design Review and Preparation

Before assembly begins, our engineers review your PCB layout and bill of materials (BOM) to identify any potential issues. This step helps prevent costly errors and ensures compatibility with our manufacturing processes.

Solder Paste Application

A thin layer of solder paste is applied to the pads where components will be placed. This paste acts as an adhesive and a soldering agent once heated.

Component Placement

Using automated pick-and-place machines, components are positioned precisely on the board. For certain components or small runs, manual placement may be employed.

Reflow Soldering

The board passes through a reflow oven, where controlled heat melts the solder paste, bonding components to the PCB pads securely.

Inspection and Quality Control

Post-soldering inspection identifies any defects such as solder bridges, missing components, or misalignment.

Through-Hole Insertion and Soldering

For through-hole components, pins are inserted and soldered by wave soldering or manual methods.

Final Testing

Functional tests verify that the assembled PCB operates correctly within the intended electrical parameters.

Packaging and Delivery

Completed assemblies are carefully packaged to avoid damage during transport and shipped according to your schedule.

Overcoming Assembly Challenges

PCB assembly can involve several challenges, but our experience allows us to tackle these effectively:

Component Availability: Supply chain disruptions can delay projects. We maintain good supplier relationships and manage inventory to minimize risks.

Design Complexity: Advanced PCBs with high component density or fine pitch require specialized equipment and skilled operators, which we provide.

Thermal Management: Some components are sensitive to heat. We adjust soldering profiles and use appropriate techniques to protect them.

Miniaturization: As devices become smaller, precise placement and inspection become even more critical. Our modern equipment meets these demands.

Sustainable Production Efforts

We are conscious of the environmental impact of manufacturing. We comply with RoHS (Restriction of Hazardous Substances) regulations to limit harmful materials in our processes. Additionally, we work to reduce waste and encourage recycling within our operations, supporting responsible electronics production.

Building Strong Partnerships

Our goal is to be more than just a supplier. We aim to be a trusted partner in your product development journey.By choosing us for your assembly needs, you gain access to:

A team of experts dedicated to delivering reliable assemblies.

Transparent communication from design through deliver.

Support for complex, custom, and standard projects alike.

A focus on quality and adherence to industry standards.

Timely service aligned with your project deadlines.

How to Get Started

If you are looking for a dependable partner, we encourage you to reach out to us. Share your project details, and we will work closely with you to provide a tailored solution that fits your technical and production requirements.

Visit our website www.arrivalelectronics.co.uk for more information or to request a quote. We are ready to support your next project with precision and care.

Navigating the Next Steps

PCB assembly is a foundational part of any electronics manufacturing process. With the right partner, you can ensure that your designs are brought to life with quality and reliability. At Arrival Electronics Limited, we bring extensive experience, industry knowledge, and a commitment to quality in every assembly we undertake. Let us help you achieve your electronics manufacturing goals with confidence and professionalism.